Sublimation Printing on Different Materials: Sublimation printing is one of the most innovative and eye-catching ways to add custom designs to a variety of materials, from clothing to marketing materials. The beauty of sublimation is that it creates vivid, long-lasting, and photo-friendly prints that are built into the material instead of sitting atop it. If you want to broaden your sublimation print knowledge and learn how to apply this art to different materials, you’ve arrived at the right place.

In this step-by-step guide, we’ll cover everything you need to know about sublimation printing tips and tricks, so you can unleash your creativity and make sure your designs look amazing on every surface.

Table of Contents

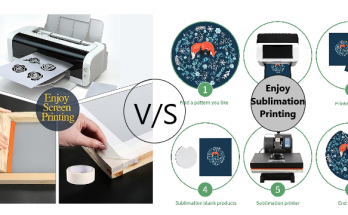

The Basics of Sublimation Printing

Let’s get back to basics again before getting into the finer details of sublimation on different materials. Sublimation printing is the process of using specialized inks (sublimation inks) to convert solid ink into a gas. Sublimation is a heat transfer method that produces high-resolution, full-color graphics on a variety of surfaces. To permanently embed the gas in the material’s surface, first the solid ink must be converted into a gas.

To print sublimation on a variety of materials, you’ll need the following:

1. Sublimation Printer

Invest in a sublimation printer designed for this specific printing method. These printers are equipped with sublimation ink cartridges and are essential for producing high-quality prints.

2. Sublimation Inks

Sublimation inks are the heart of the process. They need to be compatible with your sublimation printer and designed to work seamlessly with sublimation papers.

3. Sublimation Paper

Sublimation paper is engineered to hold the sublimation ink during the transfer process. It’s crucial for achieving vibrant and crisp prints. We suggested to have a look in the below suggested option for for a combination of paper.

4. Heat Press

A heat press machine is used to apply heat and pressure, enabling the sublimation ink to transfer from the paper to the material. Its worth to have a look in the below suggested option for heat press machine.

5. Design Software

You’ll need design software to create your custom designs and ensure they are correctly formatted for sublimation printing.

Now that we’ve covered the basics, let’s explore the tips and tricks for sublimation printing on different materials.

Sublimation Printing on Apparel

Tip 1: Choose the Right Fabric

The type of fabric you select plays a significant role in the quality of your sublimation prints. Polyester fabrics work best, as they have a high affinity for sublimation ink. Fabrics with a minimum of 50% polyester content are ideal.

Tip 2: Pre-Treat Your Fabric

Pre-treating the fabric with a polyester pre-treatment solution can enhance the vibrancy and durability of your prints. This step is particularly important for dark-colored fabrics.

Tip 3: Check for Moisture and Contaminants

Before printing, make sure your fabric is free of moisture and contaminants. Even a small amount of moisture can affect the sublimation process, so ensure your fabric is dry.

Tip 4: Time and Temperature

The correct time and temperature settings on your heat press are crucial. Always follow the manufacturer’s recommendations for both the heat press and sublimation ink.

Sublimation Printing on Ceramics

Tip 1: Choose Coated Substrates

For sublimation printing on ceramics, it’s essential to use coated substrates designed specifically for sublimation. These coatings facilitate the ink transfer process.

Tip 2: Ensure Even Pressure

When using a heat press for ceramics, make sure there is even pressure applied to the substrate. Uneven pressure can result in uneven prints.

Tip 3: Image Placement

Carefully consider the placement of your design on the ceramic item. Be aware of the curvature or shape of the item and ensure your design accounts for it.

Tip 4: Cooling and Handling

After sublimation, allow the ceramic item to cool down before handling it. This prevents smudging and ensures the design sets properly.

Sublimation Printing on Metal

Tip 1: Choose High-Quality Aluminum

Aluminum is commonly used for sublimation printing on metal. Ensure you’re using high-quality, coated aluminum sheets for the best results.

Tip 2: Print in Reverse

When sublimating on metal, it’s essential to print your design in reverse. This allows the image to appear correctly after transfer.

Tip 3: Tape Down the Image

To prevent the sublimation paper from moving during the transfer process, use heat-resistant tape to secure it in place.

Tip 4: Protect Your Heat Press

Place a protective sheet, such as Teflon or silicone, between the metal and the heat platen of your press to prevent any direct contact that could damage the metal.

Sublimation Printing on Wood

Tip 1: Select Plywood or Hardboard

When sublimating on wood, choose plywood or hardboard with a smooth and consistent surface. The smoother the surface, the better the print quality.

Tip 2: Pre-Press Your Wood

Pre-pressing the wood substrate can help remove any moisture and prepare it for sublimation. This step ensures a vibrant print.

Tip 3: Protect Your Press

Use protective sheets or silicone pads to shield your heat press from potential scorch marks or residue left behind during the sublimation process.

Tip 4: Experiment with Finishes

Consider experimenting with different finishes, such as gloss or matte. The finish can significantly impact the final look of the sublimated image on wood.

Sublimation Printing on Other Materials

Sublimation printing can be applied to various other materials, including plastic, glass, and more. The key is to select the right substrate and follow the specific recommendations for each material. Always test your process on a small sample before working on your final project.

Troubleshooting Tips

- Blurriness: If your prints appear blurry, it may be due to excessive ink or incorrect heat press settings. Adjust the settings and ensure your heat press is even.

- Fading: Fading may occur if the ink hasn’t fully penetrated the material. Ensure the substrate is compatible with sublimation and pre-treat if necessary.

- Color Variation: Inconsistent colors can result from temperature fluctuations during pressing. Maintain consistent heat press settings.

- Ghosting: Ghosting occurs when the paper shifts during pressing. Use heat-resistant tape to secure the paper.

Conclusion: Sublimation Printing on Different Materials

There are endless creative possibilities when it comes to printing on different substrates. Follow these tips and tricks to unlock the power of sublimation, and produce beautiful, durable sublimation printing on different materials. Whether you’re an experienced sublimation printer or just starting out, mastering the craft of sublimation on various substrates will open up endless creative possibilities. So, get your printer running, pick your substrate, and let your imagination run wild.

Remember, practice makes perfect – so don’t be put off by the first few challenges. With practice, you’ll get better at sublimation printing on different materials and get amazing results.

(Note: Your specific sublimation printer, inks, and materials may have unique requirements and recommendations. Always consult your manufacturer’s guidelines for the best results.)

FAQs

1. What is sublimation printing, and how does it work on various materials?

sublimation printing, also known as heat transfer printing, is the process of using sublimation ink to create high-resolution, full-color prints on a variety of substrates. The ink is converted into a gas, which then penetrates the surface of the substrate to create vibrant, long-lasting prints.

2. Can I do Sublimation Printing on Different Materials?

Sublimation printing is most effective on polyester-rich materials, including polyester fabrics and clothing, ceramic materials, metal materials (especially aluminum), wood materials, glass materials, and selected plastics. Selecting the right material is essential for the print quality.

3. Can I sublimate on cotton or natural fibers?

Sublimation is most effective on polyester and polyester-coated materials. It doesn’t work well on natural fibers like cotton because it requires a material with a high polyester content to produce optimal results.

4. Do I need special equipment for sublimation printing on different materials?

Yes, you’ll need a sublimation printer, sublimation inks, sublimation paper, and a heat press machine designed for sublimation. The right equipment is essential for achieving quality sublimation prints.

5. Are there any pre-treatment steps required for Sublimation Printing on Different Materials?

Pre-treatment can improve color life and print life, especially on dark fabrics. Here are some pre-treatment solutions for dark fabrics.

6. How do I ensure color accuracy and consistency when sublimating on various materials?

Maintaining consistent heat press settings and using high-quality sublimation inks and papers are key to achieving color accuracy and consistency across different materials.

7. Can I sublimate on curved or irregularly shaped items?

It can be tricky to sublimate on things that are curved or have an irregular shape. It’s important to think about the shape of your material and make sure your design works with it.

8. How can I avoid common issues like blurriness or fading in sublimation prints?

Properly calibrating your heat press, ensuring even pressure, and following recommended time and temperature settings can help avoid issues like blurriness or fading.

9. Are there any limitations to sublimation printing on different materials?

There are a few drawbacks to sublimation printing, like needing to use materials like polyester and having a hard time with really dark colors.

10. Can I experiment with different finishes on sublimation prints for materials like wood or metal?

Yes. You can use different finishes like gloss or matte to create different effects on wood or metal, depending on the finish. The finish affects the final appearance of sublimated images.

Hi i think that i saw you visited my web site thus i came to Return the favore I am attempting to find things to improve my web siteI suppose its ok to use some of your ideas

Thank you for visiting my web site! I’m glad you found it interesting. Feel free to use any ideas that resonate with you. If you have any specific questions or need further assistance, please don’t hesitate to reach out. Best of luck with improving your own web site!