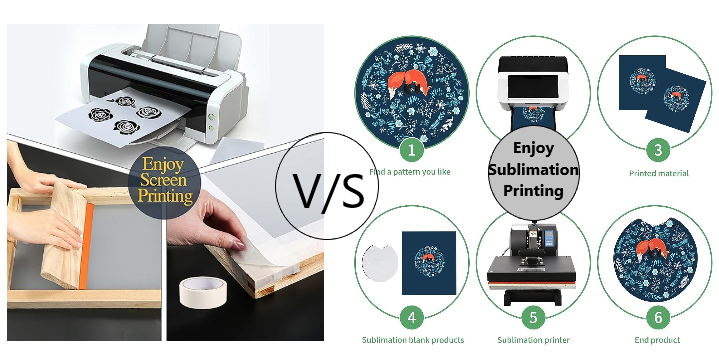

Sublimation and screen printing are two popular methods for transferring designs onto various materials, each with its unique characteristics, advantages, and disadvantages. In this blog post, we will explore the differences between these Sublimation and Screen Printing techniques to help you make an informed decision about which one suits your needs best.

Sublimation Printing

Sublimation printing is a heat-based technique that employs sublimation ink, heat, and pressure to transfer a design from a sublimation paper to a substrate, such as fabric, mugs, or metal. This method offers several benefits:

- Print Durability: Prints created by sublimation printing are ingrained in the fabric or substrate and endure a long time. This guarantees that over time, the design won’t peel, fade, or break.

- Vibrant Colors: The rich and bright colors of sublimation printing are well-known. Sharp, intricate patterns are produced as a result of the ink penetrating the substrate.

- Color Matching: Since the ink becomes a part of the substrate and lets the original color shine through, sublimation works best with white or light-colored materials.

- Complex Designs: Sublimation is capable of producing intricate designs that span the entire cloth and include gradients, various colors, and all-over prints.

- Eco-Friendly: Since sublimation produces no waste or requires the use of water, it is regarded as an ecologically benign process.

- On-Demand Fulfillment: Sublimation is well-suited for on-demand fulfillment, making it easy to customize and personalize individual prints quickly.

There are some downsides to sublimation printing, like banding and ghosting, as well as moisture and gassing issues, as well as bad colors and transfer lines on clothes. But these can be fixed by following the right guidelines and taking care of your equipment.

Screen Printing

Screen printing is a technique that employs a mesh screen to apply ink directly to the fabric or material, creating thicker and more textured prints. Screen printing has its own set of characteristics:

- Print Texture: A thicker, more textured print with a unique appearance and feel is produced by screen printing.

- Color Intensity: The prints are vivid and crisp, however with repeated washings and ironings, they could fade or shatter.

- Color Versatility: Screen printing, as opposed to sublimation, may be applied to a wide range of materials, including glass, metal, cotton, and silk.

- Quantity Production: Once the setup is finished, screen printing becomes more economical for bigger orders because of its reduced cost per print.

- Setup Requirements: It might take a while to set up screens for various designs, which limits its adaptability for small-batch or on-demand manufacturing.

- Cleanup Considerations: Screen printing may produce too much waste since it requires the use of chemicals and water to clean the screen and ink.

Sublimation and Screen Printing: Key Differences

Here’s a summary of the key differences between sublimation and screen printing:

- Print Quality and Durability: Vibrant color prints with excellent quality and longevity are possible with sublimation printing. Textured prints created by screen printing have the potential to fade or crack over time.

- Print Complexity: Screen printing works better for simpler patterns and solid forms, but sublimation works well for intricate designs with several colors and gradients.

- Fabric and Material Compatibility: While screen printing may be applied to a wide range of materials, including natural textiles and non-textile substrates, sublimation performs best on light-colored polyester or polyester blends.

- Environmental Impact: Because sublimation produces less trash and uses less water, it is said to be more ecologically friendly. Chemicals and water are used in screen printing, which might result in waste.

- Production Quantity: Sublimation printing is cost-effective for small batches and on-demand fulfillment, while screen printing is more efficient for larger production runs.

So there you have Sublimation and Screen Printing! Sublimation or screen printing, it all depends on what you need and want. Both have their pros and cons, so think about how big your project is, how complicated it is, what kind of fabric you’re using, and what’s best for the environment. Have a great printing day! 😊

If you would like more information about Sublimation and Screen Printing, check out the additional resources below.

Additional Resources:

- Mastering Sublimation Printing: Common Mistakes to Avoid – Discover how to avoid common mistakes in sublimation printing for flawless results.

- Cost Difference between Sublimation and Heat Transfer – Explore the cost differences between sublimation and heat transfer printing methods for various project scales.

- Difference between Sublimation and Heat Transfer – Explore the distinctions between sublimation and heat transfer methods for printing images or designs on various materials.

FAQs

Q1. What is screen printing?

Ans: Screen printing is a technique that uses a mesh screen to deposit ink directly onto cloth or other materials to create thicker, more textured designs.

Q2. What are the characteristics of screen printing?

Ans: Screen printing creates prints with rich color and texture, but they are prone to fading or cracking over time.

Q3. What materials are compatible with screen printing?

Ans: Screen printing works well on a range of substrates, including glass, metal, and wood, as well as non-textile materials like cotton, silk, and wool.

Q4. When is screen printing cost-effective?

Ans: In response, screen printing may be more economical for larger orders due to its reduced cost per print. On the other hand, it might not be suitable for on-demand or small-batch manufacturing.

Q5. What environmental considerations are associated with screen printing?

Ans: In order to clean the screen and ink after screen printing, chemicals and water are used, which may result in waste.

Q6. Is screen printing suitable for complex designs?

Ans: Screen printing works best for straightforward patterns with a small number of colors and basic forms.