Sublimation Printing is a printing process that utilizes heat and pressure in order to transfer patterns from sublimated paper to a variety of substrates, such as fabrics, cups, and metals. This process is renowned for its ability to produce vivid and long-lasting images that are resistant to fading and cracking. However, just like any other printing process, it can also present its own unique set of difficulties and errors. In this article, we will explore some of the most common mistakes that can be made when printing with sublimated paper and how to prevent them.

Common Sublimation Printing Problems

Before we explore the solutions, it’s essential to understand the common issues that can plague sublimation printing:

Banding: Your print will band when bright or dark stripes start to show. Low ink levels, misaligned or clogged print heads, and improper paper settings are frequently blamed for this issue.

Ghosting: A dim or hazy copy of your design is how ghosting appears. Using too much pressure or heat, or moving the paper about during the transfer process, are common offenders.

Moisture Problems: Your print may have bubbles, stains, or color changes as a result of moisture issues. These problems are typically brought on by too much moisture in the paper, substrate, or atmosphere.

Gassing Out: The term “gassing out” refers to regions of your print that are light or faded. It usually happens when you use too much heat or time, or when the ink sublimates before it reaches the substrate.

Inaccurate Output Colors: When the colors in your print differ from the original design, this problem occurs. Using the incorrect color profile, printer settings, or substrate is typically the problem.

Transfer Lines in Apparel: These are creases or markings on fabric that are frequently caused by the heat press or the paper’s edges.

How to Avoid Sublimation Printing Problems

To steer clear of these common sublimation printing issues, consider the following best practices and tips:

Clean and Maintain Your Printer Often: Consistent maintenance helps avoid issues with ink, alignment, and clogging, which can lead to color variations and banding.

Use High-Quality Sublimation Paper and Ink: Investing in high-quality sublimation paper and ink guarantees a consistent and smooth transfer, lowering the possibility of issues with gassing out, moisture, and color.

Choose the Correct Substrate: For the best adherence and vibrancy, choose substrates that are suitable with sublimation, such as polyester textiles and polymer-coated materials.

Adjust Heat and Pressure Settings: To avoid ghosting, moisture, gassing out, and transfer line problems, adjust the heat and pressure settings according to the size and thickness of your material. To do this, follow the manufacturer’s recommendations for your equipment and substrate.

Make Use of the Proper Printer and Color Profile Settings: Assign the proper color profile to your printer, ink, paper, and substrate, and modify printer settings according to the kind and caliber of the material you’re using.

By adhering to these guidelines, you can master the art of sublimation printing and produce high-quality, flawless prints. For further information and tips, check out the provided web sources below.

Happy sublimating! 😊

Additional Resources

- Difference between Sublimation and Heat Transfer – Explore the distinctions between sublimation and heat transfer methods for printing images or designs on various materials.

- Cost Difference between Sublimation and Heat Transfer – Understand the cost variations between sublimation and heat transfer printing methods for different project scales.

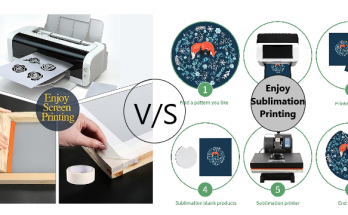

- Difference between Sublimation and Screen Printing – Discover the differences between sublimation and screen printing techniques for transferring designs onto fabrics and materials.

FAQs:

Q1. What is sublimation printing, and how does it work?

Answer: In order to transfer a pattern from sublimation paper to a substrate, such fabric, mugs, or metal, sublimation printing uses pressure and heat. It functions by changing dye-based ink from a solid to a gas, which fuses with the substance to form vivid, long-lasting pictures.

Q2. What are the most common issues in sublimation printing?

Answer: Incorrect colors, banding (stripes running across the print), ghosting (blurry duplicates), moisture difficulties (spots and bubbles), gassing out (faded patches), and transfer lines on clothing are examples of common sublimation printing errors.

Q3. How can I prevent banding in sublimation printing?

Answer: In order to prevent banding, make sure your print heads are clear of obstructions or misalignment, keep your ink levels sufficient, and utilize the recommended paper settings.

Q4. What causes ghosting in sublimation printing, and how can I prevent it?

Answer: The cause of ghosting can be attributed to either overuse of pressure and heat or paper movement during the transfer process. Make sure your paper stays in position and use the right pressure and heat settings to avoid it.

Q5. How can I address moisture issues in sublimation printing?

Answer: Excessive moisture in the substrate, paper, or surrounding air generally causes moisture problems. Store goods and paper in a dry place and keep your workspace in good operating order to prevent them.

Q6. What is gassing out in sublimation printing, and how do I fix it?

Answer: The reason for gassing out in prints is that too much heat or premature sublimation of the ink can result in faded regions. To stop gassing out, change the time and heat settings.

Q7. How can I ensure the correct colors in my sublimation prints?

Answer: Use the appropriate color profile and printer settings for your printer, ink, paper, and substrate to get correct colors. The right calibration is essential to getting the intended outcomes.

3 Comments on “Mastering Sublimation Printing: Common Mistakes to Avoid”