Discover how milking machines work and how they’ve changed the dairy farming world. Learn how these machines squeeze milk out of cows while making sure they’re comfortable and healthy. Plus, you’ll learn how milking machines can help both dairy farmers and cows, from boosting productivity to improving milk quality. Come join us on a journey to the heart of modern-day dairy farming, where efficiency and animal welfare come together.

Table of Contents

Introduction

It’s no secret that dairy farming has changed a lot in recent years. Technology has made a huge difference in making the process more efficient and keeping cows healthy. But one of the biggest changes in the industry has been the introduction of milking machines. These machines have totally changed the way we get milk from cows, and we’re going to take a look at how they work.

The Milking Machine: An Overview

What is a milking machine? Basically, it’s a machine that sucks milk out of a cow’s teat quickly and easily. It creates a vacuum around the teat, which sucks the milk out and carries it to a collection bin. Milking machines are a must-have on dairy farms because they help you get more done with less work.

How Does It Work?

The milking machine’s operation can be broken down into several key steps:

1. Teat Preparation: The cow’s udder and teats are properly cleansed to maintain hygiene before milking starts. Maintaining cleanliness is essential to avoiding milk contamination.

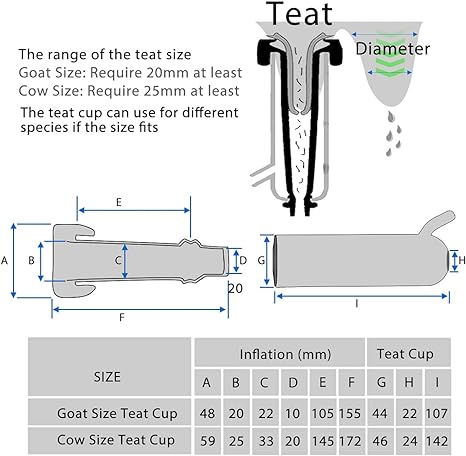

2. Teat Cup Attachment: Each teat cup that comes with the machine is wired to a pulsator. An airtight seal is formed when the teat cups are put on the cow’s teats.

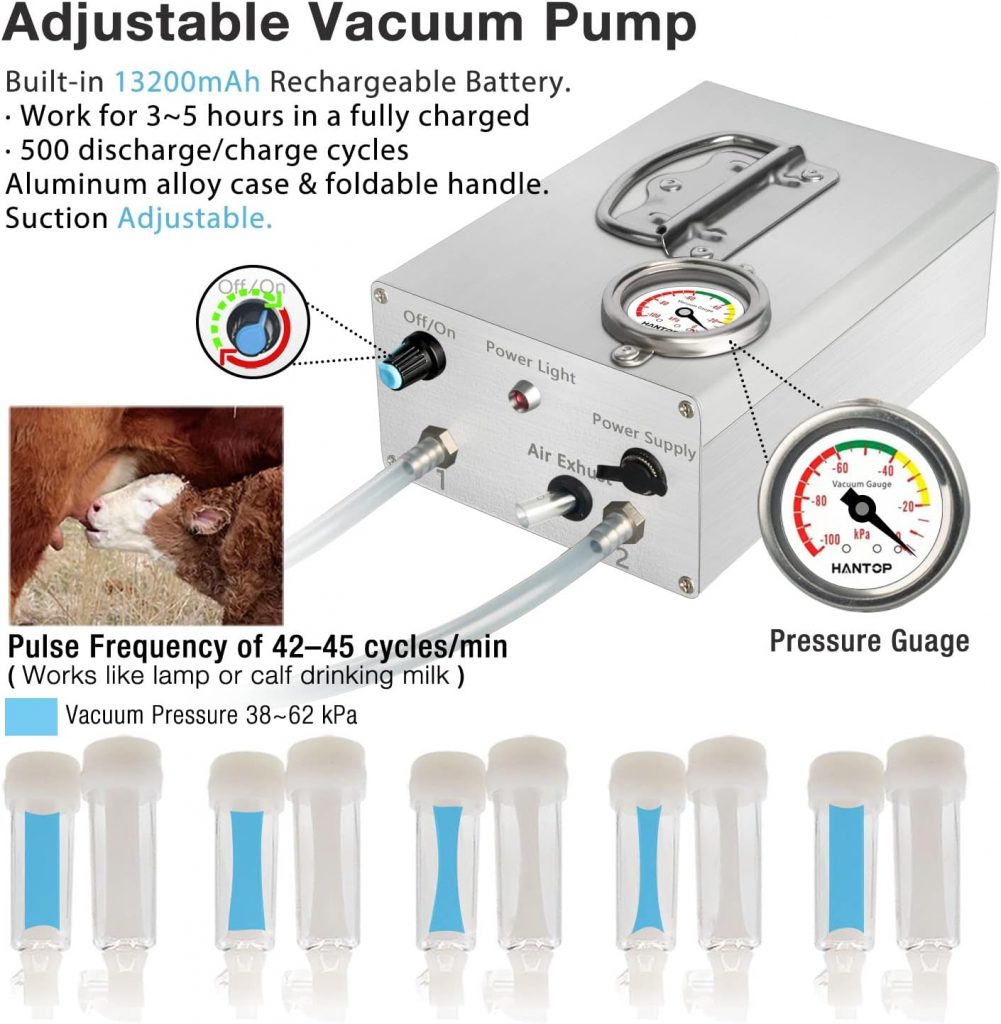

3. Pulsation: The vacuum is produced by the pulsator. In a repetitive pattern, it alternates between applying and releasing the vacuum pressure. To keep the cow happy and provide her a natural milking rhythm, this pulse simulates the motion of hand-milking.

4. Milk Extraction: The teats are gently massaged by the hoover when it is put to the teat cups, which causes the milk to flow. The milk may be pulled into the collecting system of the machine thanks to the alternating pressure.

5. Milk Collection: A system of tubes is used to move the extracted milk to a collecting container. The milk is kept in this container until it’s time to process it.

Looking for Milking Machine? Checkout our recommended option here.

The Benefits of Milking Machines

Milking technology machines offer numerous advantages, both for dairy farmers and cows:

1. Labor Efficiency: The decrease of labor is one of the biggest advantages. By automating the milking process, machines lessen the demand for physical labor.

2. Increased Milk Production: Research indicates that cows milked by machines often yield a higher volume of milk than cows milked by hand. Dairy producers will greatly benefit from this higher production.

3. Cow Comfort: The comfort of cows is a priority in the design of milking equipment. To avoid pain and harm, the pulsation rhythm and light massage replicate natural milking.

4. Improved Milk Quality: The possibility of milk contamination is reduced by the high standards of cleanliness maintained by milking machines. Milk quality is enhanced as a result of this.

Conclusion

It’s no secret that milking machines are fascinating and important to anyone in the dairy business. They’ve totally changed the way we get milk out of cows, making it easier, more comfortable, and more productive. With all the advances in technology, there’s bound to be more innovations that will make dairy farming even better, keeping cows healthy and producing better milk. It’s a big step forward for dairy farming, and it’s good for everyone involved.

FAQs

Q1: What is a milking machine, and how does it differ from traditional hand-milking?

Answer: A milking technology machine is a mechanical device designed to extract milk from cows. Unlike hand-milking, it automates the milking process, making it more efficient and less labor-intensive.

Q2: How does the milking machine ensure the hygiene of the milk collected?

Answer: By following the right cleaning procedures, machines keep their levels of cleanliness high. Before milking, the teats are properly cleansed, and the milk is gathered in a sanitary and orderly fashion.

Q3: Do milking machines cause discomfort to cows?

Answer: No, milking machines are made with the comfort of the cows in mind. To avoid pain and harm, the pulsation rhythm and light massage replicate natural milking.

Q4: Are milking machines suitable for all dairy farms, regardless of size?

Answer: The answer is that these machines may be used on both large and small dairy farms since they are available in a variety of sizes and combinations. The decision is based on the particular requirements of the farm.

Q5: What are the benefits of using milking machines over hand-milking?

Answer: The advantages include less reliance on trained labor, higher milk output, better milk quality, labor savings, and an easier way to milk cows.

Q6: How often should milking technology machines be cleaned and maintained?

Answer: To avoid contaminating milk, milking equipment should be cleaned both before and after each usage. Additionally, routine maintenance is required; light maintenance should be performed every 750 operating hours, and more extensive repair should be performed every 1,500 operating hours.

Q7: What are the considerations when choosing the right machine for a dairy farm?

Answer: Herd size, financial constraints, labor availability, equipment type, quality, safety features, and supplier reputation are all crucial considerations. The selection of an appropriate milking equipment for a farm is contingent upon each of these elements.